General Motors has been forced to temporarily shutter its assembly plant in Ingersoll, Ontario where the company builds its new electric delivery van.

A parts shortage required for the battery packs used in the BrightDrop delivery vans built at the CAMI plant is being blamed for the shutdown, which is now expected to last until at least the end of the month, according to GM spokesperson David Caldwell.

Additionally, GM is citing a shortage of railcars as a reason for slow delivery of new vehicles built at truck assembly plant in Fort Wayne, Indiana as well as plants in Mexico.

Earlier this month, GM cited BrightDrop, the new unit created to develop, produce and sell electric delivery vans, as one of the major successes in the company’s report on second quarter sales.

Battery shortage did not stall production

Caldwell, however, emphasized the parts shortage was not due to a shortage of the batteries needed to power the vehicles. The London Ontario Free Press, quoting unidentified sources from Unifor Local 88, claimed the plant shut down because it could not get enough batteries. Unifor Local 88 represent workers at the CAMI plant.

The GM-LG Energy Solutions partnership has one plant currently building cells for the Ultium batteries, though two more are planned and under construction. Neither of the new battery plants — Spring Hill, Tennessee or Lansing, Michigan — are operational yet.

Meanwhile, the GM-LG Energy battery plant near Warren, Ohio is under siege from the United Auto Workers, which organized the 1,200 workers in the plant last December.

Earlier this month, the UAW released a report detailing health and safety concerns in the plant.

According to the UAW, “An examination of the OSHA 300 log at the Lordstown facility for the first five months of 2023 reveals something quite shocking. In that short period of time, 22 people suffered OSHA recordable injuries or illnesses, more than four per month.

“This does not count injuries and illnesses that did not reach the reporting threshold. In addition, under-reporting of OSHA-recordable injuries and illnesses is common. Hence, it is quite possible that there were more than 22 injuries and illnesses that should have been recorded.

“Equally striking is that two hundred days of work were missed due to OSHA-recordable injuries and illnesses. That is 40 days each month. Moreover, employees spent 318 days on work restrictions or transferred to another job due to injury or illness — more than 60 days per month,” the union report said.

Ultium Cells rejects UAW claims

The GM-LG Energy Solutions venture, Ultium Cells, has rebutted the claims in the UAW report.

“The Ultium Cells production facility we have built in Warren, Ohio, is one of the most advanced in the world. Nothing is more important to us than the safety of our team members. There are more than 1,300 people who work at the plant that are committed to safety and quality, and they are doing an excellent job. The UAW’s characterization of the safety concerns at the facility is knowingly false and misleading,” Ultium Cells said in a statement.

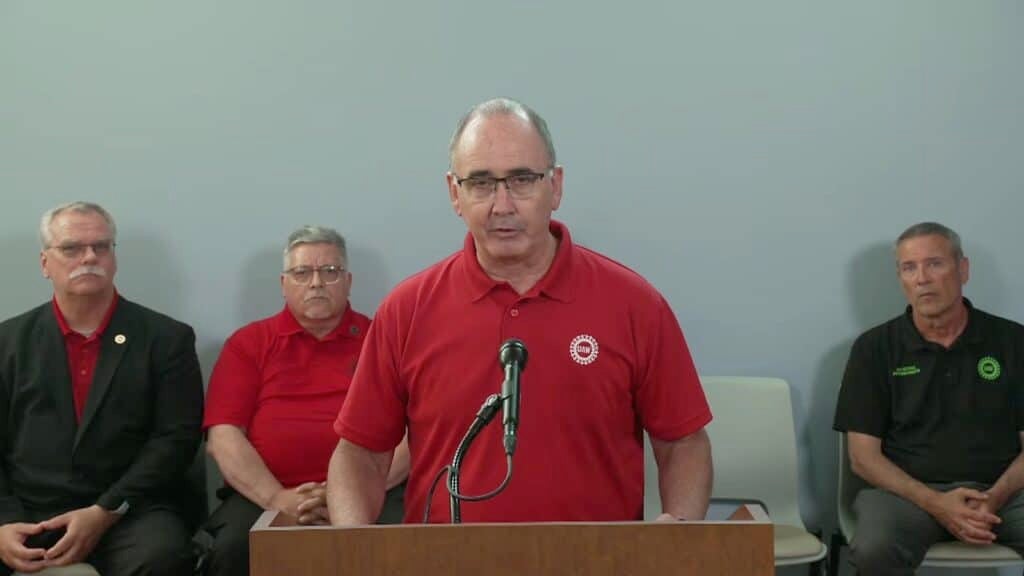

Shawn Fain, the UAW’s new reform-oriented president, also has criticized the GM-LG Energy joint venture for its low pay, describing the $16.50 per hour starting rate as “poverty wages.”

Fain and the UAW’s GM Department are also insisting the battery plants be covered by the UAW-GM master labor agreement so workers can be paid wages comparable to those of the blue-collar workers building GM internal combustion engines. So far GM has resisted the union’s demands for placing the battery plants under the next master agreement.

GM’s contract talks with the UAW began this week, and GM’s new website about the negotiations does not yet address the issues surrounding the new battery plants.

The site instead emphasized the positive aspects of GM-UAW relationship since the 40-day strike in 2019.

“Our manufacturing team is one of the reasons GM has performed so strongly over the last several years,” said Mike Perez, vice president, GM Labor Relations. “We have opportunities for every team member as we transition our footprint to an all-electric-future and I am hopeful that we can work with the UAW to maintain our momentum for the good of our people, our products and our customers.”

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Automotive / EVs, Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- BlockOffsets. Modernizing Environmental Offset Ownership. Access Here.

- Source: https://www.thedetroitbureau.com/2023/07/shortages-hamper-gms-delivery-of-new-vehicles/

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://zephyrnet.com/shortages-hamper-gms-delivery-of-new-vehicles-the-detroit-bureau/