CMS Energy’s subsidiary NorthStar Clean Energy has given Babcock & Wilcox (B&W) the green light to start initial work on converting a 73-MW coal-fired power plant in Michigan into a bioenergy with carbon capture and storage (BECCS) facility that could send “carbon-negative” power to the grid.

B&W on June 3 said the limited notice to proceed (LNTP) marks a pivotal start for the potential project, which will outfit the TES Filer City Station in Filer City, Michigan, with B&W’s biomass SolveBright post-combustion carbon dioxide (CO2) capture technology.

When the conversion project is complete, the Filer City power plant will use “sustainable biomass as fuel—coupled with B&W’s SolveBright process—to generate power with net-negative greenhouse gas emissions,” the firm said. The plant is expected to be capable of capturing up to 550,000 tons of CO2 annually, which will be permanently stored underground.

While the full contract is still being finalized, the energy and environmental services firm said it expects the “full notice to proceed” may come in the fourth quarter of 2024. So far, B&W has conducted an “extensive front-end engineering and design study conducted by B&W for the project,” it said. The LNTP will allows B&W to begin “detailed design and procurement work while the parties finalize the contract.”

“B&W’s full contract scope is expected to include engineering, design and delivery of equipment to convert the plant to use biomass fuel and add carbon capture technology. Babcock & Wilcox Construction Co., LLC, will manage the construction and mechanical scope of the project,” it added.

Heralding Fresh Momentum for BECCS

Progress for the project is notable, given an uptick in interest in BECCS—a carbon-negative technology—that integrates the myriad benefits of carbon dioxide removal (CDR) with energy production.

As POWER recently reported in detail, CDR—otherwise known as negative emissions or carbon drawdown—has recently gained quick prominence, owing to its potential to address emissions from hard-to-decarbonize sectors while removing legacy CO2 emissions. However, only a handful of technology-based CDR solutions exist so far, including BECCS and direct air capture (DAC).

Meanwhile, only a few large-scale BECCS projects are under development or have been built. So far, the largest operating BECCS project to date is the Archer Daniels Midland (ADM) ethanol plant in Decatur, Illinois, which has a capacity to capture 1 million tonnes per year (Mtpa). A much-watched power project—potentially slated to become the world’s first carbon-negative power station—is UK-based Drax Group’s effort to outfit two of four B&W 660-MW boilers at the Drax Power Station in northeastern England with BECCS using Mitsubishi Heavy Industries’ Advanced KM CDR process.

Drax has said it expects to make a final investment decision (FID) on a first Drax Power BECCS unit in 2026 and plans to potentially begin BECCS operations in 2030. If built, the UK project could remove about 8 Mtpa of CO2 per year—including 4 Mtpa of negative CO2. The CO2 would then be transported via pipeline to the North Sea and injected into geological formations below the seabed.

Drax, however, recently established a business to develop and build new BECCS plants in the U.S., noting that the country has ample sources of sustainable biomass “fiber” and carbon storage, and an “attractive investment environment for large-scale carbon removals.” Demand for high-quality carbon credits is surging in the U.S., driven by voluntary carbon markets (VCMs), which allow finance to flow toward activities that reduce and remove carbon from the atmosphere, Drax experts recently told POWER.

Drax has so far selected a first site for a BECCS new build in the U.S. South and is progressing through pre-front-end engineering design. The $2 billion project could be capable of producing around 2 TWh per year from sustainable biomass and capturing 3 Mtpa, it said. The company is targeting a FID in 2026, targeting commercial operation by 2030 and additional projects through the 2030s. “Investment in the first new-build BECCS site and subsequent developments through the 2030s will be subject to long-term CDR offtake agreements with corporate counterparties, and power purchase agreements for 24/7 renewable power,” it said. “Discussions with prospective counterparties underway.”

While a timeline for the Filer City project is uncertain, it is still in the running to become one of the first large-scale BECCS power projects built in the U.S. Its impact could be tremendous, suggested B&W Executive Vice President and Chief Operating Officer Jimmy Morgan. “By pairing sustainably sourced biomass fuel with carbon capture, our customer will be able to produce clean energy while eliminating the environmental impact of greenhouse gas emissions [GHGs],” he said.

Morgan said new several drivers are already providing momentum for a coal-to-BECCS switch. These include the U.S. Environmental Protection Agency’s (EPA’s) April 2024–finalized rule that sets final GHG emission guidelines from existing coal and oil plants. While legal challenges have already been filed challenging the rule, the measure requires many coal and gas-fired power plants to install CCS for compliance.

“As regulations require plant owners to significantly reduce or eliminate greenhouse gases from their coal-fired power generating assets, fuel-switching paired with CO2 capture can allow these assets to continue to provide economical and reliable baseload energy for many years to come,” Morgan noted.

Repowered as a Potential Carbon-Negative Power Plant

For NorthStar, an IPP, installing BECCS at Filer City offers innovation and leadership prospects, particularly as industrial decarbonization gains steam. “This project marks a step-change in real-world opportunities for our customers that are working to decarbonize and meet their business goals,” Brian Hartmann, NorthStar Clean Energy president.

NorthStar owns 50% of the Filer City power plant in partnership with Houston-headquartered industrial project development firm Tondu Corp. NorthStar, CMS Energy’s wholly owned unregulated subsidiary (formerly known as CMS Enterprises Co.), owns a 2-GW fleet primarily fueled by natural gas, solar, wind, and wood waste in multiple states, including Michigan, Arkansas, Ohio, Texas, Wisconsin, and North Carolina. Power produced by TES Filer City Station—its only coal-fired plant—is purchased by Consumers Energy, another CMS Energy subsidiary, under a long-term power purchase agreement.

CMS Energy, however, 2021, announced a sweeping proposal to phase out coal use by 2025. Consumers is currently targeting a goal to meet 90% of its customers’ needs with clean energy sources by 2040 through the execution of its Clean Energy Plan, which calls for replacing its coal-fueled generation predominantly with investment in renewable energy.

The move is bolstered by Michigan’s November 2023 enacted Energy Law, which raised the renewable energy standard from the present 15% requirement to 50% by 2030 and 60% by 2035. The law also notably sets a clean energy standard of 80% by 2035 and 100% by 2040. It considers nuclear generation and natural gas generation equipped with carbon capture as clean energy sources under the standard.

According to NorthStar, the 1990-built TES Filer City generates steam with two non-reheat Foster Wheeler traveling grate spreader stoker boilers. Tondu Corp. notes the plant is fired with coal, pet coke, tire-derived fuel, and wood waste.

“Pollutants are removed from the flue gas stream using two flue gas dry scrubbers and two baghouses,” NorthStar says. “An ABB 73-MW single-flow condensing turbine coupled to an ABB 73-MW synchronous generator converts steam to electricity.” Process steam from the plant, delivered via steam turbine extraction, is delivered to The Packaging Corporation of America, an adjacent paper mill.

A Significant Carbon Capture Opportunity for B&W

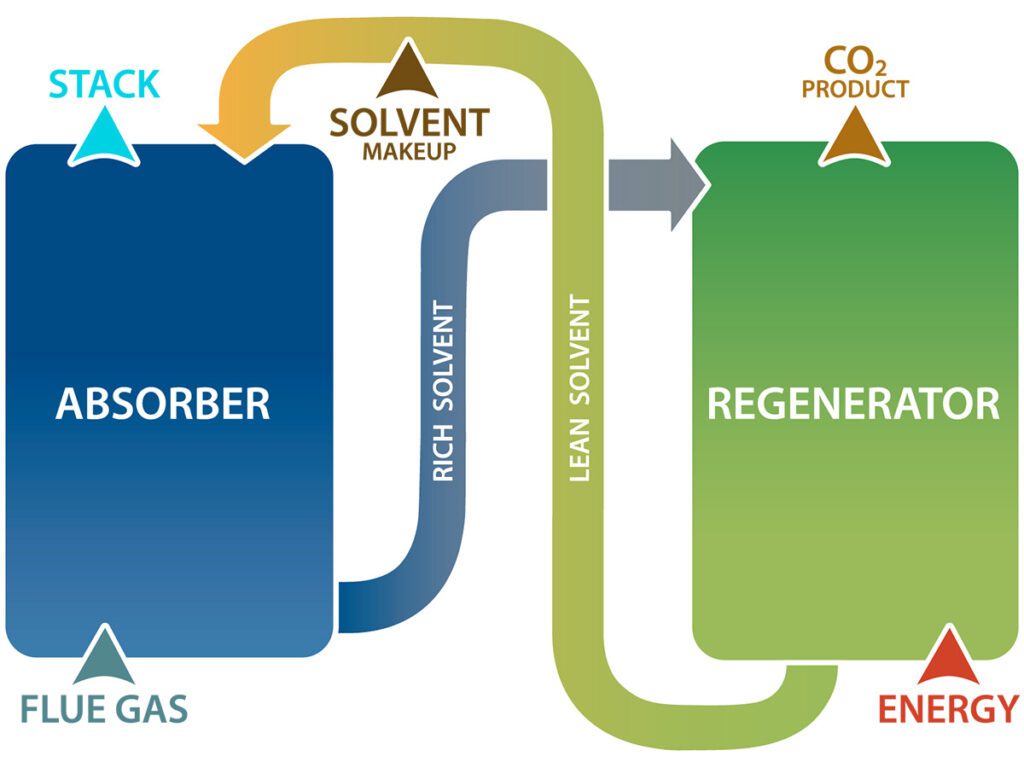

B&W’s SolveBright post-combustion carbon capture technology stems from a development program begun in 2005. Initially developed as a“regenerable solvent absorption technology scrubbing process”—which used an advanced amine-based solvent—the design has since evolved to allow solvent flexibility to meet capital and operations requirements.

The technology works by “absorbing CO2 directly from flue gas in an absorber using a regenerable solvent,” B&W explains on its website. “The CO2-laden solvent is sent to a regenerator where it is heated, and the CO2 is released as a concentrated stream for compression and transport to a CO2 sequestration hub or liquified and used for beneficial purposes. The solvent is then recycled to the absorber for additional CO2 capture.”

“For post-combustion carbon capture, B&W offers pre-treatment technologies to clean the flue gas prior to carbon capture and our SolveBright process that can be tailored to support the preferred solvent of our customers,” Joe Buckler, B&W senior vice president of Clean Energy, said last year.

B&W has since 2005 completed pilot-scale testing and designed a full-scale commercial carbon capture plant suited to capturing 1,500 metric tons of CO2 per day from a flue gas source.

A $1.4M DOE-Backed Study Is Underway

Efforts to explore whether the Filer City plant can suitably host a “net-negative” carbon capture facility have meanwhile been ongoing since at least 2014, when an initial engineering study, backed by the Department of Energy (DOE), was initiated. In August 2023, the DOE granted NorthStar $1.4 million in federal funding to develop a final engineering design package for a BECCS project that would seek to remove 95% of CO2 from flue gas at design conditions and capture 500,000 tonnes of CO2 per year.

The DOE’s study materials suggest the Filer City plant may be designed as a 30-MW baseload and process steam facility that could potentially begin construction in 2025 and be commercially operational in 2026. The study has explored an AACE (Association for the Advancement of Cost Engineering) Class 4 cost estimate (generally between –15% to –30% on the low side and +20% to +50% on the high side) to assess the viability of its business case. B&W provided BECCS support services to the study, while Sargent and Lundy provided engineering, procurement, and construction support services.

A final DOE report and presentation based on the study is expected in July 2024. So far, however, the DOE has acknowledged Filer City has many key attributes that make it an ideal candidate for conversion to BECCS.

Perhaps most significant is that based on the DOE’s biomass studies, more than 61 million tons of “unutilized sustainable biomass” is within trucking distance of the Filer City plant. “The Manistee National Forest is adjacent to the Filer Plant, and much of this forest needs the removal of dying and overcrowded trees for forest health management. In addition to locally source biomass, there are numerous ports within a short shipping distance of the Filer Dock with the capacity to meet the Filer City Plant requirement many times over,” the agency says.

In addition, it notes the plant is already “debt-free” with infrastructure that would support a cost-effective conversion. A conversion will utilize the plant’s existing dust collectors, spray dryer absorbers, and baghouse, though it will require new selective non-catalytic reduction equipment. “The existing facility and its supporting infrastructure would cost in excess of $350 million to replicate,” the DOE notes.

The plant is also located only 2,600 feet from a CO2 pipeline, enabling easy transport of captured CO2 to geologic storage sites. In addition, “An EPA approved under Subpart RR sequestration MRV plan exists that provides ample locations to sequester the captured CO2 in deep geologic formations within 10 miles of the Filer Plant.”

And, while carbon capture in the power sector has generally been limited by permitting, public engagement, and project management, the Filer plant does not need Title V EPA permitting, an electric interconnection, or acquisition of new property. The site also has an adjacent deep water port to allow for shop-built components to be delivered directly to the site, and it has operating staff already in place. Finally, over the first 12 years of commercial operation, more than “$1.2 billion million of positive economic impact will accrue to Michigan, supporting 220 permanent jobs in the depressed Northern Michigan economy,” the agency says.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://www.powermag.com/michigan-coal-plant-eyes-beccs-retrofit-could-become-first-us-facility-with-carbon-negative-power/