- DOD Posts RFP for US Army Microreactors

- Microreactor Developer Radiant Clears Safety Milestone

- SMR Developer Steady Energy Plans District Heating in Finland by 2030

- University of Michigan launches Global Fusion Forum

- AtkinsRéalis to Design Tritium Processing Facility at UKAEA

- OPG and Stellarex to Explore Fusion Energy for Ontario

DOD Posts RFP for US Army Microreactors

The US Defense Innovation Unit as part of the Advanced Nuclear Power for Installations (ANPI) program has posted a solicitation for a nuclear microreactor that can generate power for US Army bases. The RFP requires vendors plan the design, construction, operation, and management of a microreactor that can provide between 3-10 MW of power.

The US Defense Innovation Unit as part of the Advanced Nuclear Power for Installations (ANPI) program has posted a solicitation for a nuclear microreactor that can generate power for US Army bases. The RFP requires vendors plan the design, construction, operation, and management of a microreactor that can provide between 3-10 MW of power.

Currently, the US Army relies on off-site electricity providers to obtain energy in support of its critical mission and tactical readiness to ensure our nation’s security. The Army depends on off-site electricity to conduct its global missions in air, land, sea, space, and cyberspace. The accomplishment of these missions faces risks due to disruptions from extreme weather and cybersecurity attacks. While current renewable energy solutions, such as wind and solar energy are carbon-free, they are intermittent, and require battery storage or other solutions to mitigate the intermittent nature of their energy supply.

For these reasons the Army is seeking a novel approach using recent advances in the nuclear industry that can provide continuous/reliable power regardless of weather conditions to maintain military missions without the loss of electricity supply.

The objectives of the prototype include:

- Provide mission readiness through energy resilience.

- Deploy nuclear power to Army installations and demonstrate the capability of nuclear power to provide safe, secure, reliable, and environmentally compliant electricity in support of Army installation readiness goals for mission critical assets and tactical readiness.

- Address resiliency needs of the US Government’s critical infrastructure while simultaneously stimulating micro reactor development and supply chain in the U.S.

Some of the key specifications include;

- The microreactor should be operated only from the control room located within the Army installation (remote or wireless operation is not allowed).

- Remote maintenance and diagnostics capabilities that comply with relevant cyber security US Government standards, e.g., NIST 800-171 Rev. 2 for Federal Contractors, may be considered.

- All operations, maintenance, and support staff to operate the reactor for the useful life of the electricity generation asset, anticipated to be 20 years.

It can be inferred from the specifications that the RFP is not limited to light water reactor (LWRs) designs. It states that fuel enrichment must be less than 20% U235. Since most LWRs use uranium fuel at 5% or less U235, this “limitation” actually opens the door to a wide variety of advanced reactors and fuel types.

Selected proposals will be eligible for sole-sourced, follow-on contracts and production agreements for continued procurement.

A few other noteworthy specifications are that the reactor will have a site footprint of less than 5 acres at an army installation, with its corresponding protected area not exceeding 540 feet in diameter. Additionally, the plant’s irradiated core material should be removed from the base within five years of a contract’s completion or termination.

Project Pele Proceeding with Two Advanced Reactor Designs

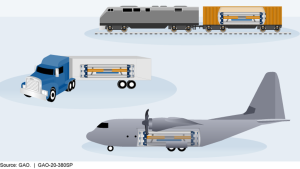

Project Pele is an effort to develop a plan to design, build, and test a microreactor at a DOD installation no later than December 2027. The project manager for the effort is the DOD’s Strategic Capabilities Office (SCO). In Spring 2022 it announced it would commit to develop a high temperature gas cooled (HTGR) mobile microreactor that can generate 1-5 GW of electrical power. Initially, SCO selected BWXT’s submission.

The BWXT design will undergo three years of testing at the Idaho National Laboratory starting in 2025.A key part of the testing effort will be to assess its capability to be disassembled, moved to another location and be put back together again.

Getting the fuel fabricated for the BWXT microreactors is a complex process. First, the uranium will come from highly enriched uranium stored at the Y–12 National Security Complex in Oak Ridge, TN. Next, the fuel has to be transformed from a metal to an oxide form at BWXT Technologies’ Nuclear Fuel Services facility in Erwin, TN. A further step is needed to downblend the fuel to enrichment levels associated with high-assay low-enriched uranium (HALEU). Finally, it will be fabricated into tristructural isotropic (TRISO) reactor fuel at the BWXT facility in Lynchburg, Virginia.

DOD SCO Adds X-Energy to Project Pele

In Fall 2023 DOD SCO added the X-Energy Mobile Nuclear Power Plant. According to SCO the contract option added X-energy so it could provide future options.

“Due to their extraordinary energy density, nuclear reactors have the potential to serve multiple critical functions for meeting resiliency needs in contested logistical environments,” said Dr. Jeff Waksman, Project Pele program manager.

“By developing two unique designs, we will provide the Services with a broad range of options as they consider potential uses of nuclear power for both Installation and Operational energy applications in the near future.”

While X-Energy is working on an 80 MW HTGR under DOE’s ARDP program, a spokesperson said the firm is working on a design that is within the SCO’s requirements.

As far as fuel for the X-Energy reactor is concerned, in October 2022 it began work on construction of its TRISO-X Fuel Fabrication Facility (TF3) in Oak Ridge, TN. The firm has a goal of commercial operational by 2025.

Benefits of Two Designs

Jeff Waksman, the Project Pele Program Manager, has emphasized in talks to the nuclear industry uses the metaphor that two heads are better than one. He says multiple designs for microreactors will give the military options for transportable microreactors.

Waksman has also made no bones about the benefits of the DOD work to deploy a fleet of transportable microreactors at domestic DOD sites. He says that there will be obvious commercial spin-offs from multiple designs, and he emphasized that as DOD places orders in volume, that this will make the Nth of a kind units cost-competitive for non-military applications.

USAF Flies a Separate Trajectory with Oklo

The Air Force is expected to task microreactor developer Oklo to site, design, build, own, and commercially operate a stationary microreactor. For its part the USAF will ink a 30-year fixed price power purchase agreement with Oklo but only after the firm obtains a combined operating license from the NRC. According the Oklo, the firm is focused on its second effort to submit a license application to the NRC. Once it is accepted, it can expect an review process than can take four or more years.

& & &

Microreactor Developer Radiant Clears Safety Milestone

(WNN) Microreactor startup Radiant Industries announced that the Department of Energy has reviewed and approved the Safety Design Strategy for its Kaleidos microreactor in the National Reactor Innovation Center’s (NRIC) Demonstration of Microreactor Experiments (DOME) test bed at Idaho National Laboratory. The test bed is located on the Arco Desert about 25 miles west of Idaho Falls, ID, at the INL’s Materials Fuel Complex. The firm’s 1 MW microreactor design is intended for off-the-grid applications at remote sites.

California-based Radiant is developing the 1 MWe Kaleidos high-temperature gas-cooled (HTGR) portable microreactor, which will use a graphite core and TRISO (tri-structural isotropic) fuel. It was one of three microreactor developers selected in October last year to receive a share of $3.9 million Department of Energy (DOE) funding to develop and test their designs in the new DOME test bed facility at Idaho National Laboratory (INL). Testing is scheduled to begin in 2026.

Radiant said the Safety Design Strategy (SDS), which describes the accepted safety analysis approach for the Kaleidos reactor, marks the initial stage in a comprehensive safety review process each microreactor developer will undertake prior to a fueled test at DOME. The company said testing in DOME will allow it to gather critical safety and performance data to support the future commercial licensing process with the Nuclear Regulatory Commission (NRC).

Radiant is currently working with INL on the next phase of the safety review, focusing on the Conceptual Safety Design Report (CSDR). The purpose of the CSDR is to summarise the hazard analysis efforts and safety-in-design decisions incorporated into the conceptual design, along with any identified project risks associated with the selected strategies.

Following its successful completion of reactor testing in the DOME facility, Radiant expects to deliver a limited number of pre-ordered Kaleidos units as soon as 2028, but after obtaining NRC license’s.

“The SDS is the cornerstone of the safety roadmap we’re building as we approach commercialization of a fueled reactor in a few years’ time,” said Radiant CEO Doug Bernauer

“The approval of the SDS is an important step towards enabling a microreactor developer to perform a test in our DOME facility,” said Brad Tomer, acting director and chief operating officer of the National Reactor Innovation Center.

The DOME test bed will repurpose the Experimental-Breeder Reactor-II containment structure at INL. EBR-II operated from 1964 to 1994, and was originally built to demonstrate a complete sodium-cooled breeder reactor power plant. It was later modified to test other reactor designs and to test materials and fuels for fast reactors, as well as generating power and heat for the site. While the reactor and much of its supporting equipment has been dismantled, the remaining 70-foot diameter, 80-foot high containment structure is particularly suited to host reactor demonstration and other nuclear projects.

& & &

SMR Developer Steady Energy Plans District Heating in Finland by 2030

(WNN contributed to this report) Finnish nuclear start-up Steady Energy aims to start work on its first small modular reactor (SMR) pilot next year. The €20 milion pilot will serve as a full-scale model of the Finnish-designed, light-water LDR-50 district heating reactor, but with an electric element rather than nuclear fuel. After the testing phase, the company aims to start building commercial scale SMRs in 2028 with the first unit in revenue service by 2030. .

The LDR-50 has a thermal output of 50MW. A few units the size of a shipping container can heat a medium-sized city. In fact, the firm plans to offer the reactor to customers for district heating. Steady Energy said it has already signed letters of intent for the delivery of up to 15 reactors with Helen, the utility supplying Helsinki, and Kuopio Energy, which serves Eastern Finland.

In Finland, more than half of the energy used for heating comes from district heating, which is mostly produced with fossil fuels, peat and biomass. Utilities are seeking ways to swiftly transit away from combustion-based heat production to new and innovative low emission alternatives such as SMRs.

Currently, the proposed locations for the pilot plant include: Salmisaari caves in central Helsinki; Huuhanmäki caves in Kuopio, the regional capital of North Savo in eastern Finland; and the power plant sites at Kymijärvi and Teivaanmäki in Lahti, a regional capital in southern Finland.

Firm Lists Its Investors

Founded last year, Steady Energy has raised around €15 Million of investment. Backers include the VTT Technical Research Centre of Finland, Lifeline Ventures, Yes VC, and the Aphorism Foundation, the investment fund of LinkedIn founder Reid Hoffman.

Tommi Nyman, the company’s chief executive, said “Heating a large city can require a log pile the size of a football field each day. Replacing this with a small, emission-free nuclear power plant that can be installed underground will eliminate the endless lines of fuel trucks and radically reduce local air pollution.”

& & &

University of Michigan launches Global Fusion Forum

The University of Michigan’s Fastest Path to Zero Initiative has launched the Global Fusion Forum, an online platform aimed at fostering international engagement and collaboration in the development of fusion energy technology.

The Fastest Path to Zero Initiative was established at the University of Michigan (UM) in 2019 as a collaboration between the university’s Energy Institute and its Department of Nuclear Engineering & Radiological Sciences (NERS).

The Global Fusion Forum aims to facilitate meaningful engagement between fusion technology developers and communities worldwide. By leveraging the expertise of the team in fusion technology, technical communication, science illustration, and UX (user experience) design, the platform will offer engaging visualizations and educational modules on fusion energy to make complex concepts accessible to a broader audience.

Users of the platform will learn about fusion energy and have the opportunity to offer their input about how key decisions concerning the development and scaleup of fusion energy systems should be made. For communities currently hosting energy facilities or those considering hosting them in the future, the Forum will provide a platform to engage with the fusion energy community, fostering dialogue and collaboration.

The Global Fusion Forum is led by Aditi Verma, an assistant professor at NERS and Fastest Path, supported by a team of interdisciplinary partners including Gabrielle Hoelzle, Kevin Daley, and Andrea Morales Coto (Fastest Path), Katie Snyder (UM Technical Communication), Steffi Diem (University of Wisconsin–Madison) and science illustrator Ana Kova. It aims to facilitate meaningful engagement between fusion technology developers and communities worldwide.

& & &

AtkinsRéalis to Design Tritium Processing Facility at UKAEA

AtkinsRéalis has been appointed by UK Atomic Energy Authority (UKAEA) to deliver the detailed design of a world-first Isotope Separation System to strengthen research into sustainable fusion delivery

The Isotype Separation System will form part of UKAEA’s Hydrogen-3 Advanced Technology (H3AT) Facility, a world-first tritium fuel cycle research facility to include a prototype-scale process plant and experimental platform, which is a scaled version of the design for ITER. The tritium capacity of this highly complex Isotope Separation System will make it the most advanced research facility of its kind, helping to enable the development of tritium fuel cycle infrastructure necessary for sustainable fusion power.

AtkinsRéalis has already completed the concept and detailed process design of the main H3AT facility, currently under construction at UKAEA’s Culham Campus, in Oxfordshire, alongside the concept and preliminary design of the Isotype Separation System.

The AtkinsRéalis team will now deliver detailed process and mechanical designs for the system, including the vital cryogenic- and ambient temperature equipment that will be required to collect, process, and recycle the tritium fuel.

AtkinsRéalis will incorporate the use of the latest digital technology, including 4D design, digital twinning and AR/VR simulation to optimize delivery and help researchers and academia to better understand the design and performance of the system.

& & &

OPG and Stellarex to Explore Fusion Energy for Ontario

Ontario Power Generation (OPG) and Stellarex Inc, a Princeton University fusion energy spinout, have signed a Memorandum of Understanding (MOU) to explore the development and deployment of fusion energy in Ontario.

OPG and Stellarex will work towards establishing a center of excellence for fusion energy in Ontario and will work together to identify potential future siting and deployment of a stellarator fusion energy device in the province.

Quick facts

The Stellarex team includes recognized experts from the international energy and fusion community, and has strong Ontario connections, including its chairperson, Richard Carty, a University of Waterloo graduate.

Stellarex has established supply-chain and fusion ecosystem relationships in Ontario and in the Canadian nuclear sector, and has MOUs with Canadian Nuclear Laboratories in Chalk River, Hatch, and Kinectrics, along with a number of Ontario’s academic institutions including the University of Toronto, Queen’s, McMaster, and Ontario Tech universities.

The stellarator approach uses extremely strong electromagnets to generate twisting magnetic fields to create the right conditions for fusion reactions.

The focus of the firm is to develop and demonstrate a prototype commercial stellarator fusion pilot plant (“SX1”), capable of producing 250 MW of electricity delivered to the grid within 12 years.

# # #

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://energycentral.com/c/ec/dod-posts-rfp-us-army-microreactors